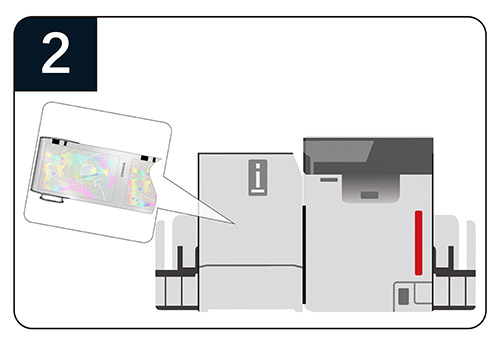

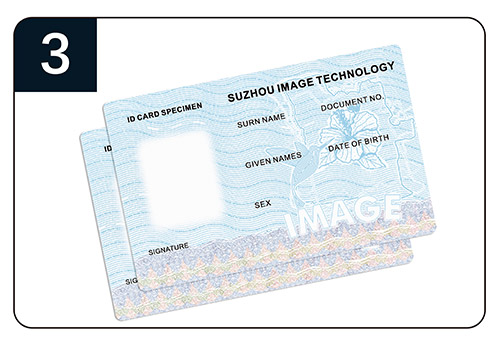

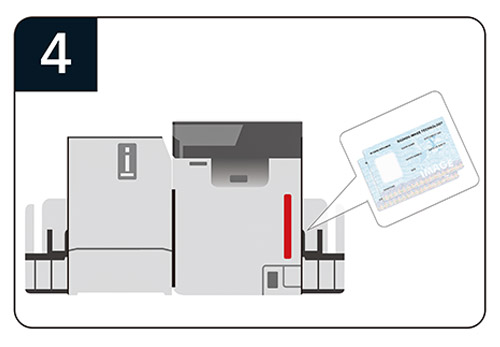

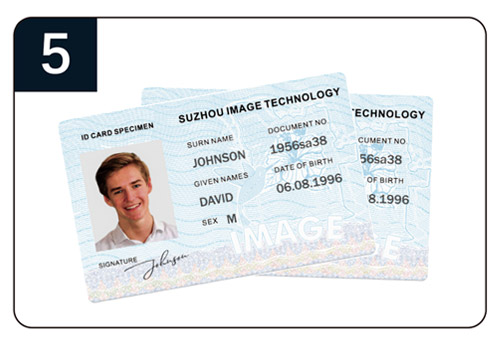

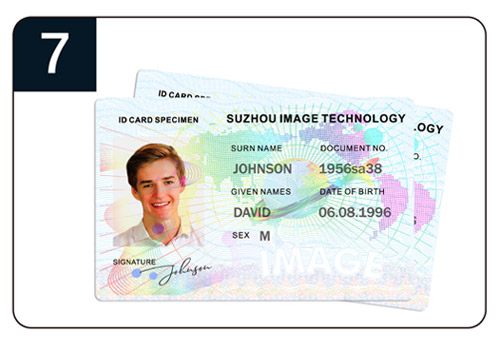

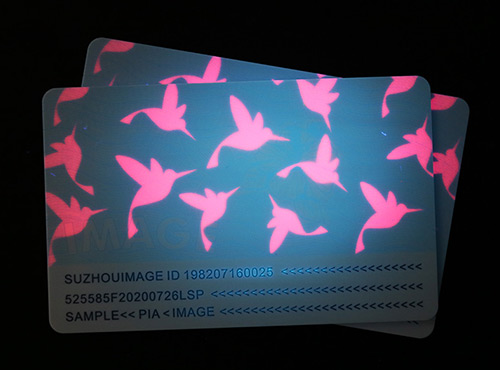

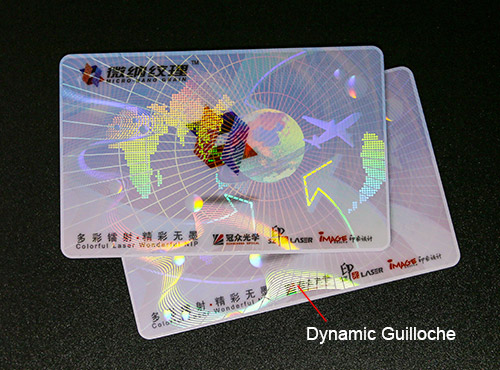

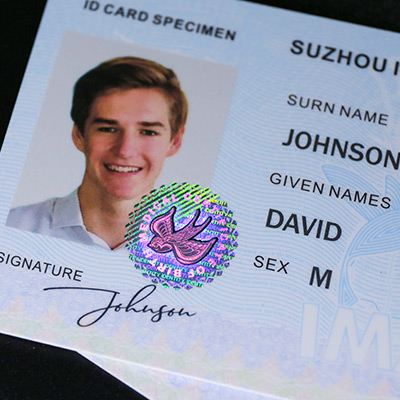

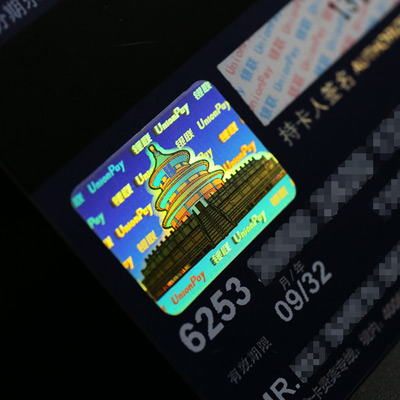

Hologram Laminate Patch

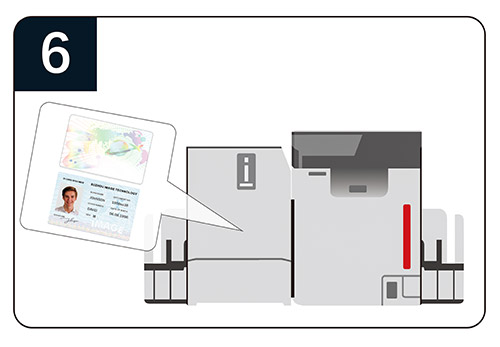

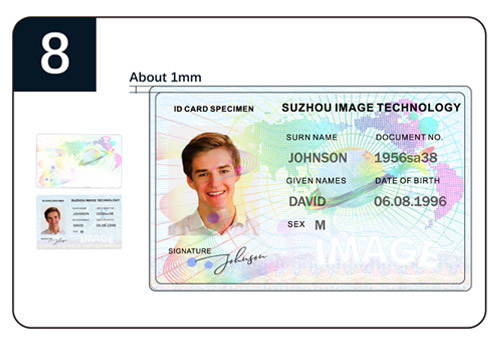

As a surface-applied thin film, holographic patch laminate can be over-laminated onto the card surface through a special id card laminator to protect your id card and personal data from tampering. After lamination, the durability of the card is improved because of its strong scratch resistance.