As the demand for personalization grows, more and more brands and manufacturers want to incorporate customized logos into hologram stickers for brand marketing and value creation.

Considering that the custom hologram has high requirements on the MOQ, the cost is also somewhat high. Some initial projects are difficult to realize personalization in this way.

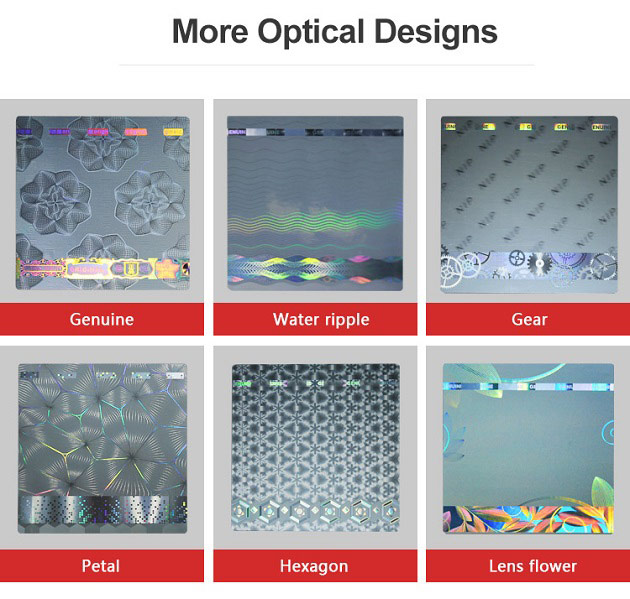

Suzhou Image has developed a series of generic optical sticker textures. These generic texture labels are made of polyester materials, have excellent printability, and can easily print the required information on texture patterns.

Although they are generic textures, they combine multiple anti-counterfeiting technologies and are extremely difficult to imitate, and the printing process will not affect the performance of the holographic effect.

Additionally, they have no mold costs, require a minimum order quantity, and can be combined with a custom printing process to become a custom holographic sticker just for your brand packaging at an affordable price.

How to do Custom Printing on Generic Hologram Sticker Texture.

These generic hologram stickers accept most flexo inks (UV and water-based), and the printed information is diverse, it can be your brand logo, QR code, bar code, serial code, etc.

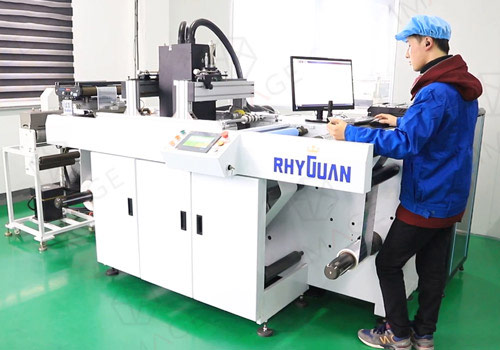

Suzhou Image provides three solutions to print the required message on generic holographic labels. They are thermal transfer ribbon (TTR), UV inkjet, and laser numbering.

The three ways can perfectly print custom messages on our generic hologram label texture and are widely appreciated by clients for their durability, excellent adhesiveness, and smooth finish. All these three solutions have their advantages and disadvantages, used for different applications and functions.

Thermal transfer ribbon(TTR) printing

TTR printing is usually for small batch production, probably less than 1 million, and its scratch resistance is good.

UV inkjet printing

UV inkjet printing is more suitable for mass production, like millions and more.

Laser numbering

Laser numbering is for labels that require higher scratch-resistant and tamper-proof functions.

One more important for numbering is scratch-resistant, among the above three. The laser number is the best. UV inkjet is the last, but we usually make a varnish coating or clear film lamination over it to strengthen the anti-scratch function.

To help you better understand, here is the form to compare the different features of the three types of numbering methods.

| Printing type | Machine cost | Workshop space | Production efficiency | Operator requirement | Scratch-resistant | Energy consumption | Production cost |

|---|---|---|---|---|---|---|---|

| TTR | Low | Low | Low | Medium | Medium | Low | Medium |

| UV inkjet | Medium | Medium | High | Medium | Low | Medium | Medium |

| Laser numbering | High | High | Very Low | Medium | High | Very high | High |

(Note: Here, Very low, Low, Medium, High, and very high are relative, and compared among the mentioned three methods only)

We will choose the suitable printing methods for your projects, considering both the quality and cost. If you still have doubts about it, please visit our previous articles, they will be helpful for you.