This foil stamping process is widely used in cosmetic packaging materials and is an important part of the post-processing technology of packaging materials. It transfers the aluminum layer of the foil to the surface of the substrate to form a special metal effect through a hot press transfer process.

The foil stamping process can be divided into cold stamping and hot stamping, among which hot stamping is further divided into hologram hot stamping, ordinary flat hot stamping, 3D stamping (commonly known as gravure and convex hot stamping), and other processes.

Today I will focus on introducing the holographic hot stamping process.

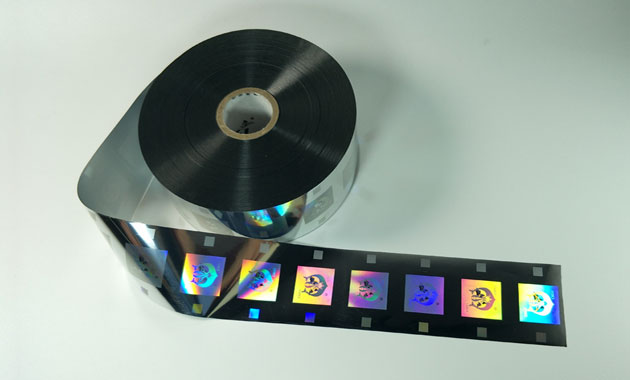

Types of holographic Hot Stamping Foil

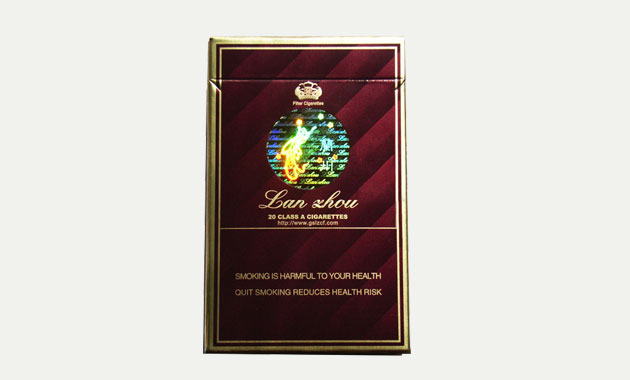

The holographic hot stamping foil is a special hot stamping process, that mainly includes random and register hot stamping. It uses the anti-counterfeiting pattern on the foil, which not only greatly improves the anti-counterfeiting performance of the product, but also improves the level of the product. It is mainly used for various carton packaging that needs an anti-counterfeiting function.

It’s a great combination of laser holographic images with good anti-counterfeiting effects and hot stamping technology so that the product has both anti-counterfeiting performances while being an excellent visual appearance.

Working Principle of Hologram Foil Stamping

Using the hot stamping equipment, the hot melt adhesive layer and the release layer on the hot stamping hologram material are heated and melted by the heated hot stamping mould.

Under certain pressure, the information layer of the hot stamping material (the holographic grating stripes) is separated with the PET substrate Separation, so that the aluminum foil information layer and the ironing surface are bonded and integrated to achieve a perfect combination.

In the next post, we will introduce the registered hot stamping process, welcome to leave a message for more exchanges.